Advance UV Systems provide high quality ultraviolet (UV) systems and spare parts to potable water and wastewater treatment customers.They manufacture their own range of UV systems for a wide range of applications including drinking water disinfection, food & beverage water disinfection, process & commercial water disinfection, hot water disinfection, legionella control, swimming pool disinfection, aquaculture, sugar syrup disinfection, tank headspace disinfection, ultrapure water, greywater reuse, sewage treatment, wastewater disinfection and many more.

Document download

Innovative self-cleaning microfiber water filters for treatment as fine as 2 micron. Features:

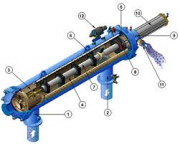

The Amiad EBS Series are automatic filters, with an electric self-cleaning mechanism. The “EBS” filters range in flowrates of up to 7200 m³/h (32000 US gpm), with screens designed ranging from 800-10 micron filtration degree. Inlet/Outlet flanges are available from 8”-36” diameter. Features:

Galaxy Batteries are manifolded batteries of automatic self-cleaning Arkal Spin Klin disc filters, designed as a highly efficient solution for high flow rate applications and for all types of water, including seawater. Features:

Amiad FILTOMAT M100 Series are range of automatic filters, ideal for remote installation sites, with a water-driven self-cleaning mechanism that doesn’t require external power source to operate. With their various screen areas the M100 models support flow-rates of up to 400 m³/h (1760 US gpm), with filtration degrees of 500 down to 80 micron and inlet/outlet diameters from 2”-10”. Features

The Amiad Omega Series are automatic filters, with multiple screens operated by a single electric self-cleaning mechanism. The “Omega” filters range in flowrates of up to 5,000 m³/h (22,000 gpm) and from 10 -500 micron filtration degree. Inlet /Outlet flanges are available from 8”- 32” diameter.

The Filtration Process is; raw water enters from the filter inlet and passes through the multi-screens. Clean water flows through the filter outlet. The gradual dirt build up on the inner multi screen surface causes a filter cake to develop, with a corresponding increase in the pressure differential across the multi-screens. A pressure differential switch senses the pressure differential and when it reaches a pre-set value, the self-cleaning process begins. The Self-Cleaning Process of the filter is carried out by multiple suction scanners with an option for SLN (Spring Loaded Nozzles) which scans across the multi-screens by a common gear operated by up to 3 electric motors. The DP switch signals to open the exhaust valves creating a high velocity suction stream at the nozzle tip which “vacuums” the filter cake from the multi screens. During the self-cleaning process, which takes approximately 25 seconds, filtered water continues to flow downstream.

Document download

The Arkal SpinKlin SK 2” Compact filter is a stand alone, polymeric, automatic disc filters with a patented self-cleaning backwash mechanism.

The Arkal SK 2” Compact filter is for flow rates of up to 20 m3/h (88 gpm) with filtration degrees ranging from 20 – 400 micron. Inlet /Outlet - 50 mm (2”) diameter. The discs are stacked on the SpinKlinTM spine and assembled according to pre-determined water filtration requirements. During filtration, the discs are compressed by means of a pre-loaded spring and differential pressure, forcing the water to pass through the grooved disc surface, thus trapping the solids.Activated by a pre-determined time command or differential pressure, the filter enters backwash mode. The inlet valve port shuts as the drain valve port opens. Water flows through a bypass filter screen into the outlet valve and into the filter. During the backwash process, pressure is released and the spine’s piston elevates, releasing the compression on the discs. Tangential jets of filtered water are then forced through the nozzles positioned along the spine. At this stage the discs spin freely, loosening the trapped solids which are then flushed out.

Document download

Durable high quality Steel Filters for wide range of filtration applications. Features:

UV-Guard are specialists in Ultraviolet (UV) water disinfection. UV-Guard designs, manufactures and supplies an extensive range of water purification equipment, as well as spare parts for all major UV brands. UV-Guard’s UV water purification systems can be used to produce ultra-pure water. No micro-organism is known to be immune to UV - even the chlorine resistant Giardia and Cryptosporidium. Economical and efficient, UV water disinfection is chemical free, with no impact on taste and no corrosion problems. UV-Guard’s water purifiers are performance proven and flexible across a range of uses. Each system is designed according to the application and project requirements. Maintenance is easy with lamps able to be replaced without interrupting the water flow.

Document download